CMC alloy process(copper molybdenum copper alloy) - reverse coagulation as follow:

Reverse coagulation method is the German Mannesmann Group and Technical University of Aachen in 1989 jointly developed a unique concept, near-net-shape strip casting technology. It was master sheet or strip, to a certain speed reverse coagulation from the molten liquid passing through the low melting point metal, composites from the inside out so that the master surface solidified into composite strip, and then directly in rolling at high temperatures, to obtain surface roughness, dimensional accuracy of the method of preparing the composite material.

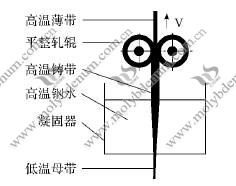

The principle is shown below. This method was first used to produce the composite thin strip, the principle point of view but also for the production of base material properties of the substrate and a large difference in the composite material, so that once made concern. At nine Ming et al prepared by this method copper/steel bimetal composite class materials were studied and found composites straight, neat, no holes and peeling, element diffusion layer formed at the interface to form a good metallurgical bond .

Pic. Reverse Solidification Process Coagulation Layered Composite Materials

Reverse coagulation composite as a bimetal composite materials of the new technology, though not yet in the Mo/Cu multilayer composite material has been applied, but the method for producing copper/steel bimetal composite material success, no doubt to CMC alloy preparation technology innovation provides a possibility.

If you have any interest in our CMC alloy(copper molybdenum copper alloy) or other molybdenum alloy products, please feel free to contact us by email: sales@chinatungsten.com,sales@xiamentungsten.com or by telephone:86 592 512 9696.